Tailor-made for your success

Standard was yesterday. Today, flexibility matters.

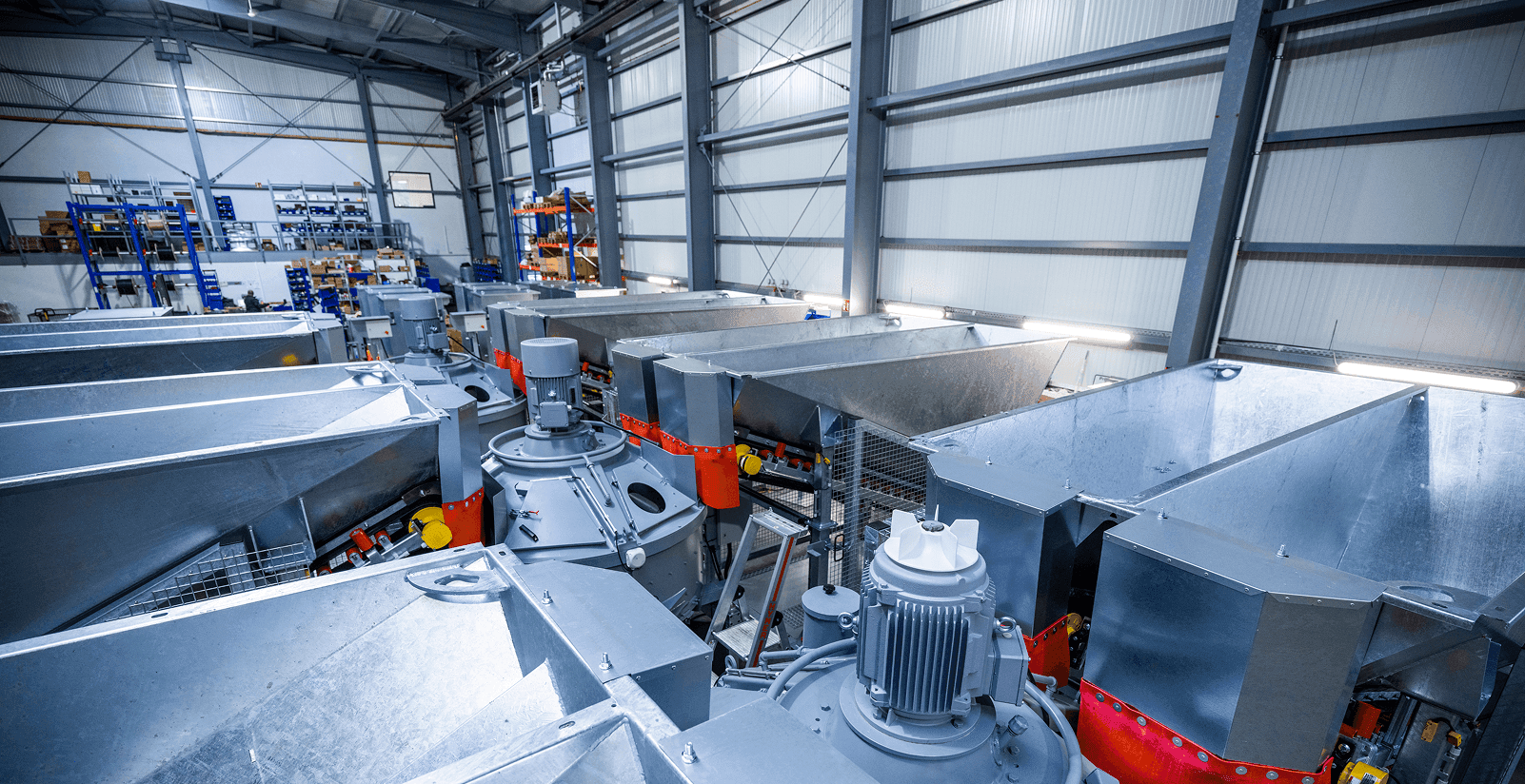

At Beton2Go, we understand that every construction site has its own requirements — and every building-material supplier or landscaping company pursues individual goals. That’s exactly why we don’t offer off-the-shelf solutions. Our concrete stations, building-material kiosks, and bulk-material dispensers are designed precisely to fit your needs. Modular, scalable, and future-proof.

Your requirements. Our solution.

Whether you have a property with limited space or a large storage area — our systems adapt to your conditions. Thanks to their modular design, our concrete stations can be flexibly configured from just four components. You decide:

Arrangement of the modules — corner setups also possible

Accessories such as self-service terminal, customer account system, or storage tanks for water-independent operation

Size and number of storage chambers

Capacity and performance of the mixing module

Length of the discharge conveyor belt

And if you have additional requirements, we’re happy to think further. Our engineering and development teams work closely with you — personal, pragmatic, and solution-oriented.

Quick to set up – ready for use, individually tailored

Every Beton2Go concrete station is assembled and operational within a short time — including transport, installation, commissioning, and training. We also integrate special solutions such as increased discharge heights, additional silos, or smart features for digital sales directly upon request. Particularly convenient: Our system can be operated completely contactlessly and controlled via magnetic card or QR code.

Curious what your setup could look like? Click here to go to the configurator.

Custom solutions that grow with you

The market is changing. New customers arrive, requirements increase, building materials become more sustainable. We don’t just provide technology that fits you and your services — we also deliver the flexibility you need to respond to change. Our stations can be expanded or upgraded at any time. This keeps you competitive in the long term — whether you want to offer new mixes, integrate recycled materials, or equip additional locations.

Personal. Close. And always available.

What our customers particularly appreciate: Our service doesn’t end with delivery. Our sales experts, technicians, and service staff are always directly reachable — by phone, on site, or via remote support. Because we know: Anyone who provides customized technology must also provide customized support.

Want to design your concrete station individually?

Get in touch with us — and let’s find the perfect solution for your business together.